150HS-R Slurry Pump

Summary Description

1)Capacity: 360—828m³/h

2)Head: 10—61 m

3)Flow parts materials: Cr26 alloy

4)Allowable mating Mac power: 300 kw

$3670.00

PRODUCT DETAILS

| Product description |

|

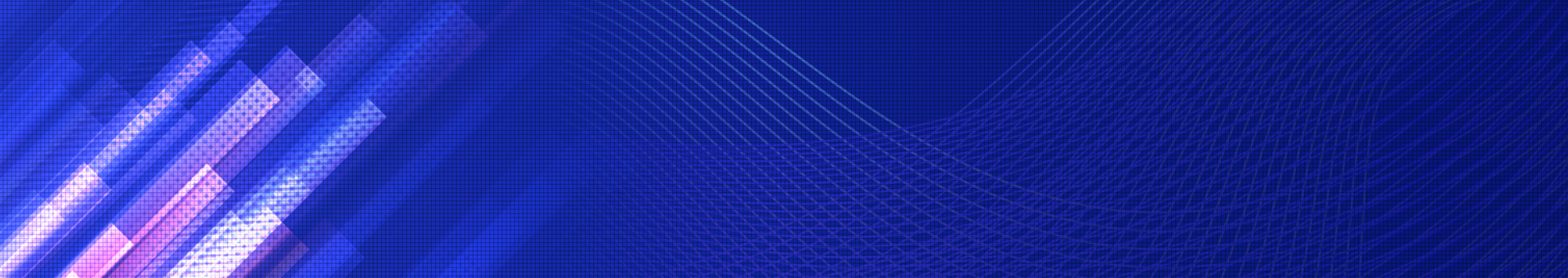

Type MS, HS, and HHS pumps are cantilevered, horizontal, centrifugal slurry pumps. They are designed for handing abrasive, high slurries in the metallurgical, mining, coal, power, building material and other industrial departments etc. The pumps of this type also may be installed in multistage series. |

| Details Images |

| Work environment |

| Product Paramenters |

| Pump Model | Performance | ||||

| Capacity(m³/h) | Head (m) | Speed(rpm) | Max Power(KW) | NPSH(m) | |

| 25HS-B | 12.6~28.8 | 6~68 | 1200~3800 | 15 | 2-4 |

| 25HHS-C | 16.2~34.2 | 25~92 | 1400~2200 | 30 | 2-5 |

| 40HS-B | 32.4~72 | 6~58 | 1200~3200 | 15 | 3-8 |

| 50HS-C | 39.6~86.4 | 12~64 | 1300~2700 | 30 | 4-6 |

| 50HHS-D | 68.4~136.8 | 25~87 | 850~1400 | 60 | 3-7 |

| 75HS-C | 86.4~198 | 9~52 | 1000~2200 | 30 | 4-6 |

| 75HHS-E | 126~252 | 12~97 | 600~1400 | 120 | 2-5 |

| 100HS-D | 162~360 | 12~56 | 800~1550 | 60 | 5-8 |

| 100HHS-S |

324~720 | 30~118 | 600~1000 | 560 | 3-8 |

| 150HHS-S-A |

468~1008 | 20~94 | 500~1000 | 560 | 4-9 |

| 150HS-R |

360~828 | 10~61 | 500~1140 | 300 | 2-9 |

| 200MS-E |

666~1440 | 14~60 | 600~1100 | 120 | 2-8 |

| 200HS-ST |

612~1368 | 11~61 | 400~850 | 560 | 2-8 |

| 250HS-ST |

936~1980 | 7~68 | 300~800 | 560 | 2-8 |

| 300HS-TU |

1260~2772 | 13~63 | 300~600 | 560 | 3-9 |

| 350HS-TU |

1368~3060 | 11~63 | 250~550 | 1200 | 3-8 |

| 450HS-TU |

2520~5400 | 13~57 | 200~400 | 1200 | 5-9 |

| Working principle |

|

|

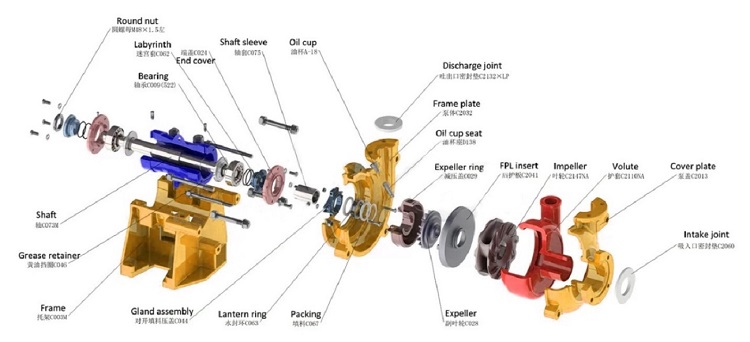

| Types of accessories |

| Company Profile |

| Production workshop corner |

| Use of Site |

| Enterprise production certificate |

| Customer Visit Photos |

| Packaging Transport Photos |

| FAQ |

Q: How can I make order online?

A: Send email or message(whatsApp/ wechat) us.you can ask any question ,after we confirm the detail, we can make order.

Q: Do you have MOQ limit?

A: The MOQ is 1 set.

Q: Which payments are acceptable?

A: T/T, L/C, Western Union, Paypal.

Q: Which shipping terms are available?

A: By sea, air, Express.

Q: How about the delivery time?

A: Delivery time is normally 3-7 working days after confirm the money. Depends on your quantity.

Q: What's your warranties?

A: 1 year after delivery.

Q: Can I buy parts separately?

A: Yes, all of the pump spare parts can buy separately.

| Similar Product Recommendations |

Message

Select customer service

QQ Online Customer Service

QQ Online Customer Service

QQ Online Customer Service

QQ Online Customer Service

QQ Online Customer Service